-

-

Manufacturing strength

-

Sustainable development

-

-

29

2024

-

04

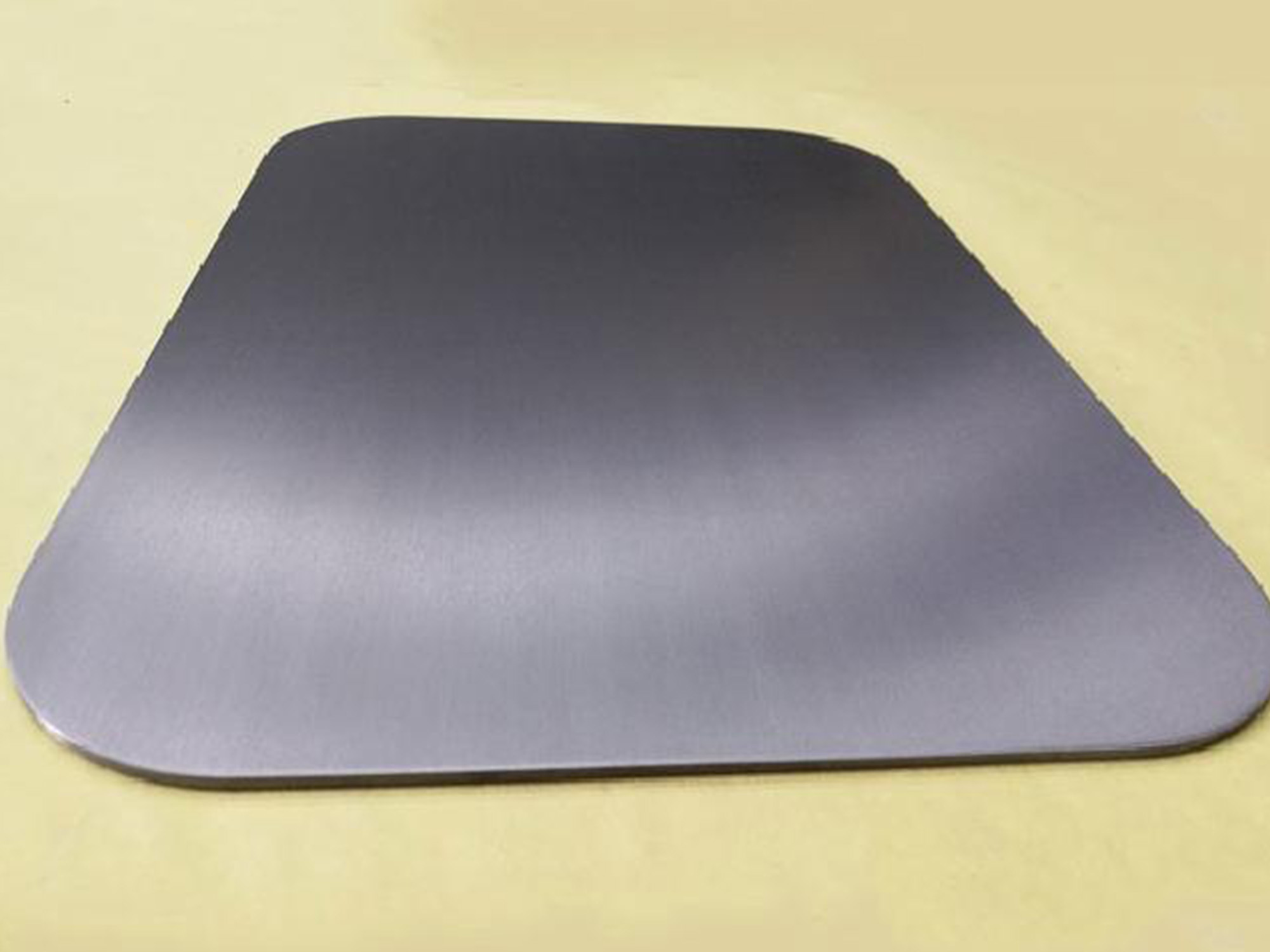

Niobium Target A Versatile Material for Sputtering Applications

Niobium (Nb), a transition metal with a unique combination of physical and chemical properties, has found significant use in various industrial applications. One of its key roles is as a sputtering target in the field of thin-film deposition technology. Sputtering is a process where atoms or molecules are ejected from a solid target material and deposited onto a substrate to form a thin film. Niobium targets are particularly valued due to their ability to produce films with specific characteristics that are essential in numerous technological applications.

Properties of Niobium Target

Low Thermal Expansion: Niobium has a low coefficient of thermal expansion, which helps maintain the stability and integrity of the deposited films over a range of temperatures.

Corrosion Resistance: It exhibits excellent resistance to corrosion by many acids and alkalis, making it suitable for applications requiring long-term durability.

Superconductivity: Niobium is a superconductor below its critical temperature, a property that is exploited in the production of high-performance magnets and electronic devices.

Applications of Niobium Target

The utility of niobium targets spans several advanced industries:

Electronics: Niobium oxide is used as a dielectric material in capacitors for its temperature stability and high dielectric constant.

Optical Coatings: For producing anti-reflective and protective coatings on lenses and optical devices, niobium targets are sputtered to create films with desirable optical properties.

Superconducting Films: In the fabrication of superconducting films for particle accelerators and magnetic resonance imaging (MRI) machines, niobium targets play a crucial role.

Barrier Layers: Niobium and its compounds are employed as barrier layers in semiconductor devices to prevent diffusion of materials and improve device performance.

Manufacturing Considerations

The production of niobium targets involves careful manufacturing processes to ensure consistency, purity, and the required properties for sputtering. Techniques such as vacuum arc melting or powder metallurgy are used to create targets with high density and minimal porosity.

As a testament to its versatility, the niobium target remains an indispensable component in the realm of sputtering technology. Its contribution to the creation of advanced materials and thin films underscores its importance across various sectors, especially those pushing the frontiers of science and innovation. As we continue to seek higher performance and more efficient technologies, the demand for niobium and its derivatives is expected to grow, further cementing its status as a critical material in modern industry.

wechat : Mr Hu

Contact address: Daguling Village, Huangxing Town, Changsha County, Hunan Province

Sales:(0086)-(0)731-86882787(Domestic)

Sales:(0086)-(0)731-86882259(Domestic)

TEL: (0086)-18932424084

Copyright©2023 Changsha Southern Tantalum and Niobium Co., Ltd. Powered by www.300.cn SEO Tags